- Alaskan Yachts

- Azimut Yachts

- Back Cove Yachts

- Beneteau Yachts

- Benetti Superyachts

- Bertram Yachts

- Boston Whaler

- Broward Yachts

- Buddy Davis Sportfish

- Burger Yachts

- Cabo Yachts

- Catamarans

- Carver Motoryachts

- Center Console

- Chris-Craft Yachts

- Cruisers Yachts

- DeFever Trawlers

- Dufour Sailboats

- Fairline Yachts

- Feadship Yachts

- Ferretti Yachts

- Filippetti Yachts

- Formula Yachts

- Fountaine Pajot Cats

- Grady-White

- Grand Banks Trawlers

- Hargrave Yachts

- Hatteras Yachts

- Hinckley Picnic Boats

- Horizon Yachts

- Hydra-Sports

- Intrepid Boats

- Jarrett Bay Sportfish

- Jeanneau Yachts

- Kadey-Krogen Trawlers

- Lazzara Yachts

- Lekker Boats

- Luhrs Sportfish

- Marlow Yachts

- Maritimo Yachts

- Marquis Yachts

- Mazu Yachts

- McKinna Motoryachts

- Meridian Yachts

- Midnight Express

- MJM Yachts

- Mochi Craft

- Neptunus Motoryachts

- Nordhavn Trawlers

- Nordic Tugs

- Numarine Yachts

- Ocean Alexander Yachts

- Ocean King

- Offshore Yachts

- Outer Reef

- Oyster Sailing Yachts

- Pacific Mariner Yachts

- Palmer Johnson Yachts

Dufour Yachts :: How the Boats Are Built (Part 2)

All Dufour Yachts are built in our facility in La Rochelle, France. They all combine fine hand craftsmanship with innovative high-tech construction techniques. It all starts with the hull, and this is how it’s done.

Click here to read Part 1 of how Dufour Yachts are built

Both hulls and decks are built of fiberglass in a state-of-the-art facility in La Rochelle, France, but they are actually built in very different ways. As explained in Part 1, each hull is built of layers of hand laid fiberglass and resin in open molds.

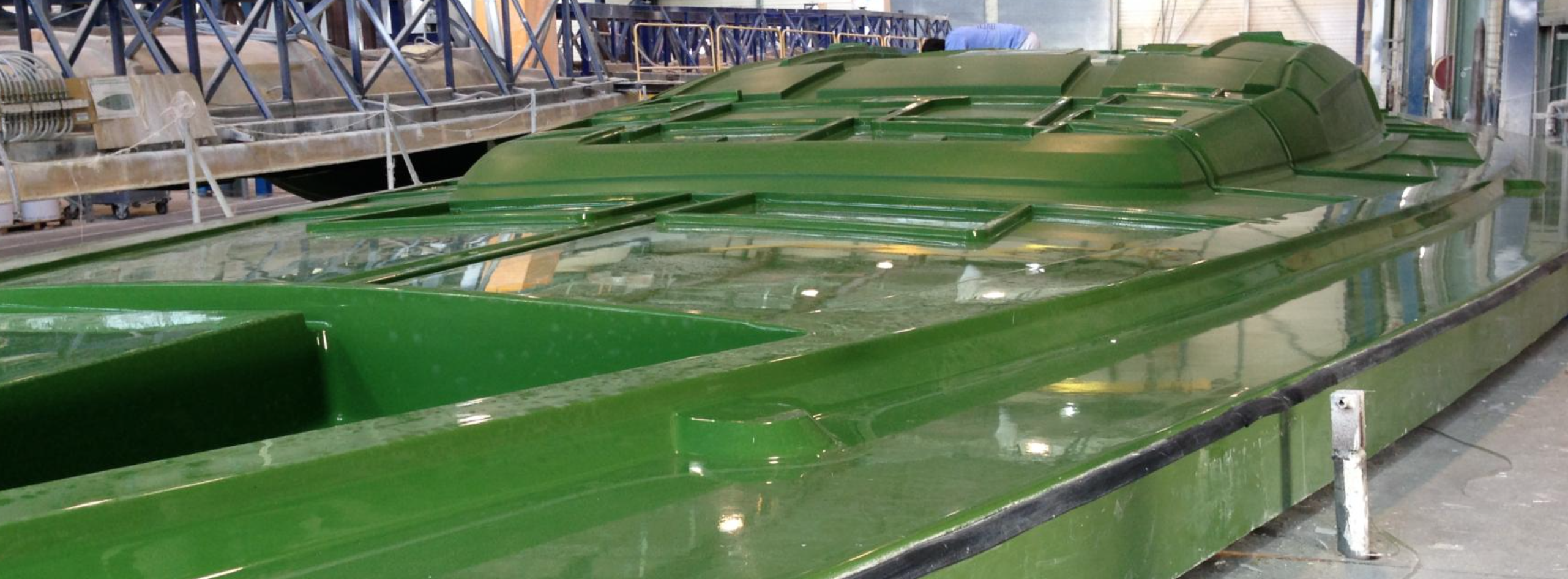

Decks, on the other hand, are “injection molded” in closed, 2-piece molds. This process allows the finished decks to come out of the molds strong and smooth, so smooth in fact that a finished boat won’t need a liner, but, it does require sophisticated engineering and incredible attention to detail during construction.

Injection molding requires the entire deck to be laid out with specific layers of fiberglass and reinforcing material in high load areas like winch pads and jib tracks etc to laid up all at once on the “bottom” part of the mold that is first sprayed with gel coat that will form the smooth outer layer of the deck (pictured above).

Then the “top” which is also covered with a layer of cured gel coat is lowered on to the bottom part that’s laid out with the required sandwich material (pictured above). The two parts are then joined and form an air tight seal and then the magic happens.

It’s not actually “magic” but, once the two parts of the mold are sealed, workers can then start “injecting” the resin into the mold. The resin is pumped in through hoses (pictured above) and the seal insures complete resin saturation. This is ideal because it results in a strong deck without requiring excess resin.

Flawless precision out of the mold

Injection molded decks are virtually flawless (on both sides) when they come out of the mold.

Custom cut out areas for install

Then workers use jigs to cut out the areas for ports and hatches as well as drill all necessary holes to install all the deck hardware.

Attaching the deck hardware

Then the deck hardware is attached before the deck is the lowered on to the hull.

And the best part is, the underside of the deck is beautiful. This allows for increased headroom (since no deck liner is needed) and the sleek, modern look Dufour Yachts are known for.

For more information about Dufour Yachts, contact Denison Yacht Sales, the exclusive dealer for Dufour Sales@denisonyachtsales.com | +1 310.821.5883

Latest News & Events

|

Riviera 5600 Sport Yacht Platinum Edition World Premiere at Miami Boat Show 2026Australia’s premier luxury motor yacht… |

|

Sunseeker 82 Ocean Enclosed Makes Its US Debut at Miami Boat Show 2026The newest addition to Sunseeker’s Ocea… |

|

The Ultimate Collection: A One-of-a-Kind Car CollaborationAbove & Beyond captures the spirit of the oc… |

|

Get Ready For FRANK 11Something exciting is on the horizon for the yac… |

|

SACS Rebel 55 Performance Rib Walkthrough: The Ultimate Maxi Rib and Dayboat HybridFounded in 1989 across four facilities in Italy… |

|

2025 Year in Review: Superyacht Market ReportA Strong, Broad-Based Year for Brokerage Activ… |

|

55′ Sunseeker Superhawk 2024 Sold by Josh FaigA new 55′ Sunseeker built in 2024, was sold by J… |

|

On the Water with HCB: Testing the 56 Sueños GIXThe Denison Yachting marketing team recently s… |

|

Yacht On Display in Fort Lauderdale [LMC Open House]Safe Harbor LMC Broker Open House // Thursday, F… |

|

155 Christensen SEA CLASS Open House in USVI [Feb 17, 2026]*Re-scheduled Due to Bad Weather*2PM // Thursd… |

|

87′ Cheoy Lee 2014 Sold by Sidney Ambroise [BBELLA]BBELLA, an 87′ Cheoy Lee built in 2014, was sold b… |

|

Meet the Gunboat Team at the Miami Boat Show 2026 [MIBS]Denison Welcomes Gunboat at MIBS Denison Yacht… |