- Alaskan Yachts

- Azimut Yachts

- Back Cove Yachts

- Beneteau Yachts

- Benetti Superyachts

- Bertram Yachts

- Boston Whaler

- Broward Yachts

- Buddy Davis Sportfish

- Burger Yachts

- Cabo Yachts

- Catamarans

- Carver Motoryachts

- Center Console

- Chris-Craft Yachts

- Cruisers Yachts

- DeFever Trawlers

- Dufour Sailboats

- Fairline Yachts

- Feadship Yachts

- Ferretti Yachts

- Filippetti Yachts

- Formula Yachts

- Fountaine Pajot Cats

- Grady-White

- Grand Banks Trawlers

- Hargrave Yachts

- Hatteras Yachts

- Hinckley Picnic Boats

- Horizon Yachts

- Hydra-Sports

- Intrepid Boats

- Jarrett Bay Sportfish

- Jeanneau Yachts

- Kadey-Krogen Trawlers

- Lazzara Yachts

- Lekker Boats

- Luhrs Sportfish

- Marlow Yachts

- Maritimo Yachts

- Marquis Yachts

- Mazu Yachts

- McKinna Motoryachts

- Meridian Yachts

- Midnight Express

- MJM Yachts

- Mochi Craft

- Neptunus Motoryachts

- Nordhavn Trawlers

- Nordic Tugs

- Numarine Yachts

- Ocean Alexander Yachts

- Ocean King

- Offshore Yachts

- Outer Reef

- Oyster Sailing Yachts

- Pacific Mariner Yachts

- Palmer Johnson Yachts

Inside Turkey's Superyacht Industry: Denison's Tour of 10 Turkish Shipyards

Denison’s five-day tour reveals the evolution of Turkey’s custom yacht building capabilities

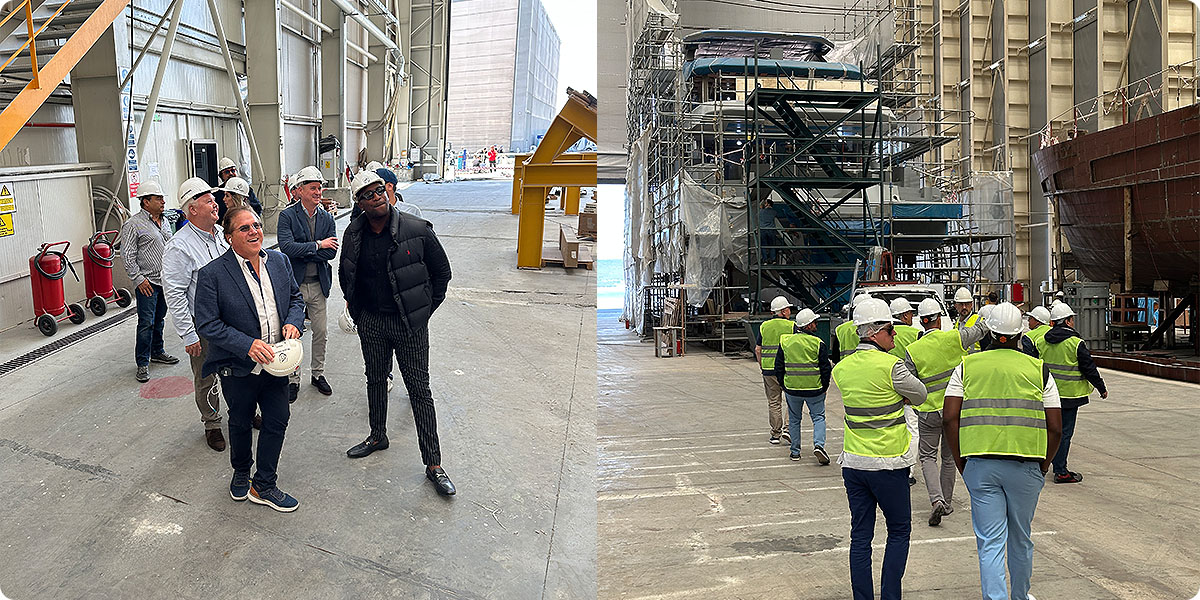

Turkey’s superyacht industry has undergone a dramatic transformation over the past two decades, evolving from a value-focused market to a sophisticated hub for world-class custom yacht construction. In May 2025, Denison Yachting’s team embarked on an intensive five-day tour of Turkey’s premier shipyards, visiting ten facilities across Istanbul and the surrounding regions to assess the current state of Turkish yacht building and identify emerging opportunities for international clients.

Alex G. Clarke, a yacht broker with Denison’s Fort Lauderdale office, brings a unique perspective to the Turkish shipyard evolution. “I have now been doing business in Turkey for close to 20 years and to see the evolution of their yachting industry over this time has been impressive. Today there is a combination of well established shipyards like Turquoise, Numarine, & Bilgin mixed with newcomers working hard to gain some of the market share,” Clarke observes.

“What is most impressive to me is the advancement in quality and the facilities that can rival some of the more well-known brands being built in Italy & Europe,” Clarke notes.

On why shipyard tours are an important annual tradition for the company, President Bob Denison has stated “Shipyard tours are great opportunities to not only gain insights from the world’s best builders, but also a time for team‑building and connecting with our industry in a unique way.”

As Peter Quintal, Denison Yacht Broker, put it: “We toured to better understand the quality, innovation, and available projects Turkey offers. Seeing shipyards like Bilgin, Mazu, and Turquoise in action provides the comfort we need to confidently present these options to our clients.”

Day One: Bilgin Yachts – Setting the Standard for Large-Scale Production

The tour commenced with Bilgin Yachts, one of Turkey’s most established and respected builders, specializing in yachts ranging from 50 to 120 meters. Operating from over 79,000 square meters of facilities across Turkey, Bilgin has established itself as a leader in large yacht construction through its sophisticated dual-facility approach.

Bilgin’s production process begins in Yalova, where hulls and superstructures are assembled, followed by a technical launch and transfer to the Istanbul headquarters for comprehensive outfitting. This facility houses specialized departments for mechanical, electrical, piping, and interior works, along with dedicated spaces for marine furniture, stainless steel fabrication, upholstery, and hydraulics.

The shipyard’s impressive portfolio includes 26 delivered yachts, with notable vessels like the 80-meter LEONA (2023) and TATIANA (2021), both featuring H2 Yacht Design interiors and Unique Yacht Design naval architecture. Currently, Bilgin maintains an ambitious order book with 13 projects under construction or on order, including the flagship 86-meter Bilgin 282, scheduled for delivery in 2026.

Peter Quintal was particularly impressed by the facility’s organization. “Bilgin Yachts stood out to me. Very clean and organized shipyard that seems to be running an efficient shipyard,” he noted, highlighting the importance of systematic operations in large yacht construction.

Yacht broker Russ Schafer added “Bilgin is doing some really cool things in the 50m to 90m range, featuring innovative options like gyro stabilized beds.”

The team’s Marketing Director, Landen DeGraff, emphasized the human element that sets Bilgin apart. “The team behind Bilgin were world-class: intelligent and friendly as could be and I really enjoyed getting to know them,” he observed, underlining how personal relationships remain crucial in the global superyacht industry.

Day Two: Numarine, SES Yachts – Innovation in Mid-Range Construction

The second day featured visits to two distinctly different builders, showcasing the diversity within Turkey’s yacht construction landscape. Numarine, representing the modern face of Turkish yacht building, operates from a purpose-built, 35,000-square-meter climate-controlled facility in Gebze.

Numarine’s approach draws heavily from aviation and automotive industries, utilizing advanced techniques like vacuum infusion and sophisticated composites to create lightweight yet strong structures. The facility houses Europe’s largest 5-axis CNC machine, enabling millimetric accuracy during mold creation – a level of precision that rivals the most advanced European facilities.

The shipyard’s production capacity allows for up to twelve yachts annually in the 22-45 meter range, with all key components produced in-house. This integration provides exceptional quality control and customization capabilities, appealing to clients seeking semi-custom solutions. Numarine’s impressive delivery record includes 48 vessels, predominantly in the popular 26XP and 37XP series, with multiple units delivered annually.

Denison’s relationship with Numarine exemplifies the growing confidence in Turkish builders. “Denison has sold 16 Numarine yachts over the past four years, 12 of which were new construction projects. They have made a big push into the US market and to see their quality evolve and improve has been extremely rewarding,” Clarke reports.

“I really liked the 40XP Numarine with its mediterranean design style, I think that will be popular,” included Shafer.

SES Yachts, established in 1977, represents a different approach with its focus on fully custom construction. Operating from facilities within Tuzla Shipyard, SES constructs vessels using various materials including GRP, epoxy laminated wood, aluminum, and steel. Their current projects include a 26-meter and 42-meter hybrid yacht, demonstrating the shipyard’s commitment to sustainable propulsion technologies.

Day Three: Magnolia Yachts, Mengi Yay, and Bosphorus Exploration

The third day combined shipyard visits with cultural immersion, featuring tours of two distinctive builders followed by an afternoon cruise of the Bosphorus. Magnolia Yachts, founded in 2019 as part of the Yardimci Shipping Group’s expansion into luxury yacht building, represents the newest generation of Turkish builders leveraging decades of commercial shipbuilding experience.

Magnolia’s approach emphasizes complete customization, treating each project as a unique commission. The shipyard currently has three 41-meter projects in various stages, with Hull 01 in build and scheduled for 2025 delivery. Notably, Denison holds the Central Agency for the 41-meter Magnolia project, demonstrating our confidence in this emerging builder.

“Combining the expertise of Greg C. Marshall and Gökhan Yardimci, we are so excited to give potential owners and yachting enthusiasts the chance to step onboard this stunning superyacht next year. Magnolia 41m blends innovation, craftsmanship and a rich family legacy to create a truly exceptional boat, and we are confident that she will make major waves in the industry,” comments Peter Quintal, Yacht Broker at Denison Yachting

Mengi Yay Yachts provided one of the tour’s most impressive demonstrations of organic growth and innovation. With over five decades of experience dating back to 1964, Mengi Yay has evolved into a sophisticated builder of advanced composite, steel, and aluminum yachts from their 19,000-square-meter Tuzla facility.

Ioannis Petrocheilos, Yacht Broker & Business Development Executive from Denison’s Monaco office, was particularly impressed by Mengi Yay’s strategic development. “I think Mengi Yay are onto something. You can see how they’ve grown organically within the last years by acquiring new plots next to their shipyard and building new sheds within their facility,” he observed. “Also, the Mengi Yay S1 has an amazing design, with two yachts of the model already at sea.”

The shipyard’s current order book demonstrates impressive diversity, with seven projects ranging from 35 to 52.6 meters under construction. Notable upcoming deliveries include the Serenissima II (47m) featuring Nuvolari Lenard design and the innovative Virtus XP models (52.6m) with Van Oossanen naval architecture.

Day Four: Yacht Factory, Mazu, and Sirena – Diversity in Design Philosophy

The fourth day showcased three builders with distinctly different approaches to yacht construction, from large-scale production to boutique craftsmanship. Yacht Factory (NOA/Adele) impressed the team with its massive 200,000 square meter facility equipped with an 800-ton travel lift and advanced equipment capable of servicing superyachts and megayachts.

The facility’s scale and capabilities represent significant investment in infrastructure, with specialized design offices and furniture workshops that blend aesthetics and functionality. Each NOA vessel features interiors designed by Italy’s Hot Lab Design, built and furnished by Yacht Factory’s skilled artisans. Currently, the shipyard has three projects in build or nearing completion, including the 47.8-meter NOA 48 and a custom 45-meter vessel.

Mazu Yachts provided one of the tour’s most compelling stories of entrepreneurial vision and innovative design. Established in 2011, Mazu operates from a focused 7,000-square-meter indoor facility with additional outdoor space, deliberately limiting production to ten yachts annually to ensure personalized attention.

The shipyard’s founder and owner, Halit Yukay, made a strong impression on the Denison team. Petrocheilos noted: “Halit is young and passionate about what he is doing. Unlike many other owners he is personally invested in this company.”

DeGraff echoed this sentiment, particularly appreciating Mazu’s design philosophy: “Halit Yukay, owner of Mazu Yachts, is a young guy with a smart feel for what works best out on the water. I really liked hearing about their design choices and felt he and the team had a good taste for style.”

Mazu’s current order book includes two 92DS models under construction, featuring innovative designs by Alfa Marine Design and Profjord. The 92DS represents a unique approach in the 28-meter category, offering distinctive styling and performance characteristics that set it apart from conventional designs.

Petrocheilos recognized Mazu’s potential in the competitive mid-size market: “Mazu seems to be an up and coming shipyard in the 25-35m range, their designs are innovative and now that they have already built Hull 01 I think they should be considered for future projects more seriously. The Mazu 92 DS is one of the few yacht models of its size that is truly different than others.”

Sirena Yachts, as a division of the diversified Kıraça Group, operates from a substantial 155,000-square-meter facility and has gained recognition for long-range motor yachts and explorer-style vessels. The shipyard’s collaboration with internationally respected naval architects including German Frers and Cor D. Rover ensures each model blends performance with elegance through optimized semi-displacement hulls.

Day Five: Dunya and Turquoise – The Pinnacle of Turkish Yacht Building

The tour concluded with visits to two shipyards representing the absolute pinnacle of Turkish yacht construction capabilities. Dunya Yachts, led by founder Sedat Ergun since 2005, has transformed from a family waterfront property into a high-tech superyacht facility capable of accommodating vessels up to 110 meters.

Dunya gained international recognition with the award-winning 73-meter AXIOMA, establishing the shipyard’s reputation for meticulous detail, quality construction, and seamless project management from concept to delivery.

The team was particularly impressed by Sedat Ergun’s candid assessment of the Turkish industry. DeGraff noted: “Sedat really stood out to me. I admired his extreme transparency about the state of yacht building in Turkey today, outside of the company’s own scope, and appreciated his time with the team.”

Quintal reinforced this impression: “He provided the best insight of the current yacht building environment in Turkey.”

Turquoise Yachts provided the tour’s grand finale, representing Turkey’s most prestigious custom yacht builder. Widely regarded as the country’s premier facility for fully bespoke superyachts over 50 meters, Turquoise has built an international reputation through its no-shortcuts philosophy and advanced technology integration.

The shipyard’s comprehensive in-house capabilities span from design and engineering to interior outfitting and production, ensuring precision throughout the build process while accelerating timelines. This integrated approach results in vessels known for their silence, efficiency, and adherence to the highest international specifications.

Turquoise’s engineering team, with over half comprised of alumni from Turkey’s historic naval technical university, supports innovation at every level. The facility utilizes cutting-edge tools including 3D modeling, CFD analysis, and automated systems that rival facilities in Northern Europe.

The shipyard’s impressive portfolio includes 27 delivered vessels ranging from 27 to 79 meters, with notable recent deliveries including the 79-meter NYMPHEAS (2025) with Harrison Eidsgaard interiors and the 75-meter INFINITE JEST (2023) featuring Sinot Yacht Architecture & Design.

Turquoise’s current order book reflects strong international confidence, with six major projects under construction including the ambitious 87-meter Project Vento and the 79.9-meter NB78.

Clarke emphasized the significance of two projects: “On the larger side Denison has two substantial new construction projects with Turquoise — ABOVE & BEYOND which are 65m & 80m respectively both designed by Bannenberg & Rowell. Two world class projects designed by one of the most well known naval architects in the world in B&R.”

The selection of Burak Akgul, Turquoise’s representative, particularly impressed Petrocheilos: “Definitely Mr. Burak Akgul of Turquoise yachts stands out, you can immediately see more than 25 years of experience in huge shipyards in Europe and in Turkey as well as a natural passion about yachting in him.”

Industry Insights: Key Learnings and Market Observations

The tour revealed a Turkish yacht building industry that has successfully transformed from a cost-focused market to a quality competitor on the global stage. Aderbal Coelho Junior, approaching the tour with specific learning objectives, was “genuinely surprised by how advanced Turkey’s metal yacht construction has become. The design, flexibility, and technical capabilities were better than expected.”

His overall assessment reinforced Turkey’s emerging position: “It’s clear Turkey is gaining serious ground in custom yacht building — especially in steel and aluminum. Strong infrastructure, competitive pricing, and a growing international mindset make it a great option to present to clients.”

Quintal highlighted the industry’s trajectory: “The quality is improving year by year which is attracting some major yacht designers and yet pricing is still reasonable compared to Italian and Northern European yards.”

DeGraff, as Marketing Director, emphasized the tour’s value for client engagement: “Getting to tour the in-build and completed yachts with the team behind each project explaining every area, decisions taken, and vision provides the best knowledge base for a marketer to pass on to potential clients.”

Clarke’s perspective on future market development includes active participation in industry events: “I’ll be speaking at the Turkish Super Yacht Summit in November and excited to gather with industry leaders to discuss the future of this ever developing market.” This engagement demonstrates the growing recognition of Turkey’s role in the global superyacht industry.

Speak With A Superyacht Specialist